Manufacturing parts for railways and defense involves specialized processes due to the stringent safety, reliability, and performance requirements of these sectors.

Description

Here’s an overview of the manufacturing processes and considerations for both railways and defense parts:

Railways:

Rolling of Rails: Rails are typically manufactured through a rolling process where steel ingots are heated and passed through a series of rollers to achieve the desired shape.

Sleepers: Concrete or wooden sleepers are molded and treated for durability.

Interior Components: Seats, lighting, and other interior elements are often produced through a combination of molding, casting, and assembly processes.

Overhead Wires and Third Rail Systems: Manufacturing involves precision engineering for the wires or third rail components.

Interlocking Systems: Complex electronic systems are manufactured to ensure safe train operations.

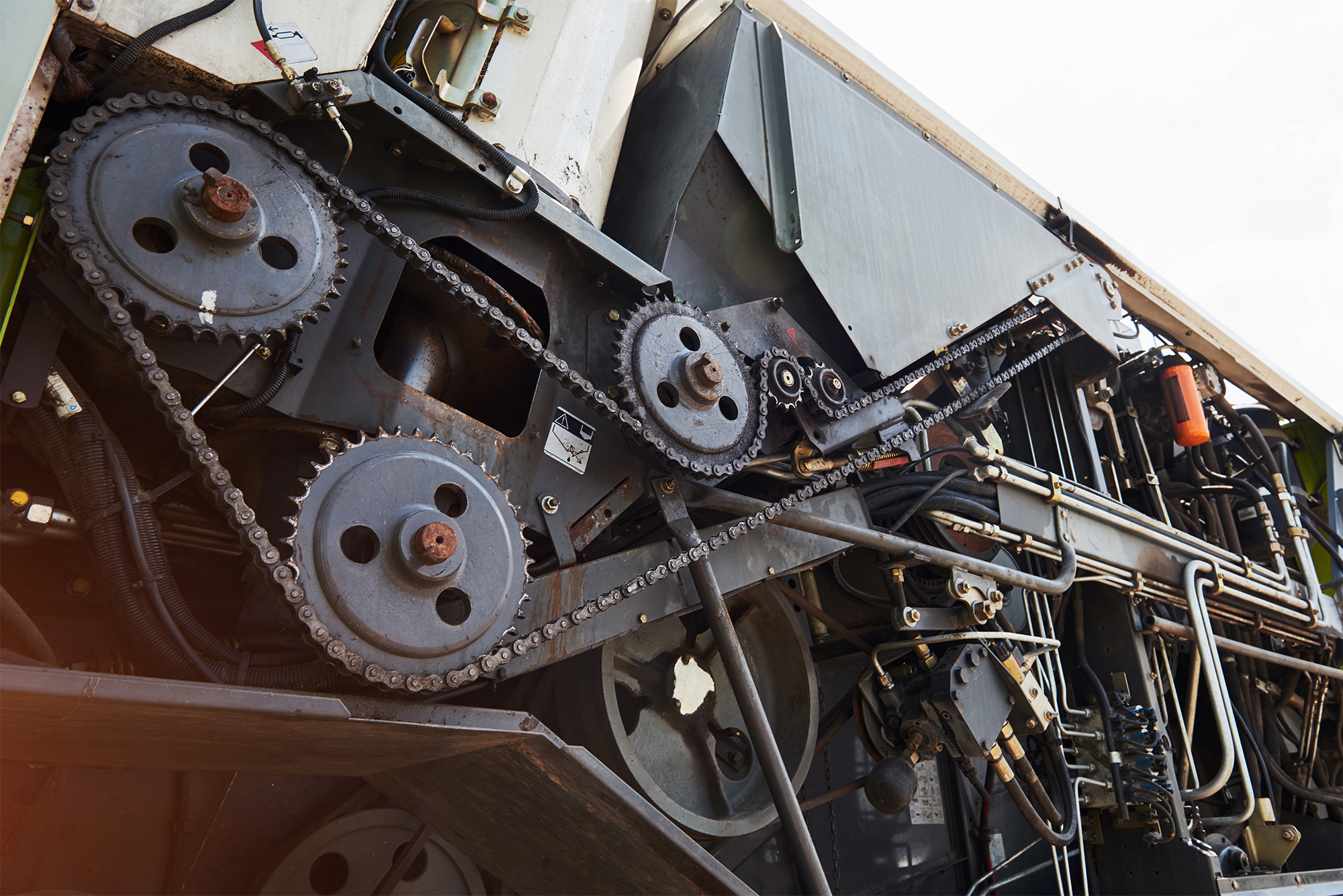

Railroad Maintenance Vehicles: Custom fabrication involving mechanical and electrical engineering.

Inspection Systems: Precision manufacturing for sensors and inspection equipment.

Defence:

Tanks and Armored Vehicles: Precision machining and welding for armored hulls and components.

Infantry Equipment:Precision manufacturing for firearms and ammunition.

Ships and Submarines: Shipbuilding involves complex welding, metalworking, and assembly processes.

Fighter Jets and Bombers: Aerospace manufacturing for airframes and components.

Transport Aircraft: Advanced manufacturing for cargo holds and structural components.

Radar and Surveillance: Precision manufacturing for radar antennas and sensor systems.

Radios and Satellite Communication: Precision manufacturing for electronic components.

Manufacturing processes for both railways and defense parts involve a combination of traditional techniques and cutting-edge technologies. Quality control, adherence to specifications, and compliance with safety standards are critical aspects of the manufacturing process in these sectors. Collaboration between engineers, designers, and manufacturers is essential to ensure that the parts meet the stringent requirements of railways and defense applications. Additionally, the use of advanced materials and technologies, such as additive manufacturing (3D printing), is becoming more prevalent in these industries.